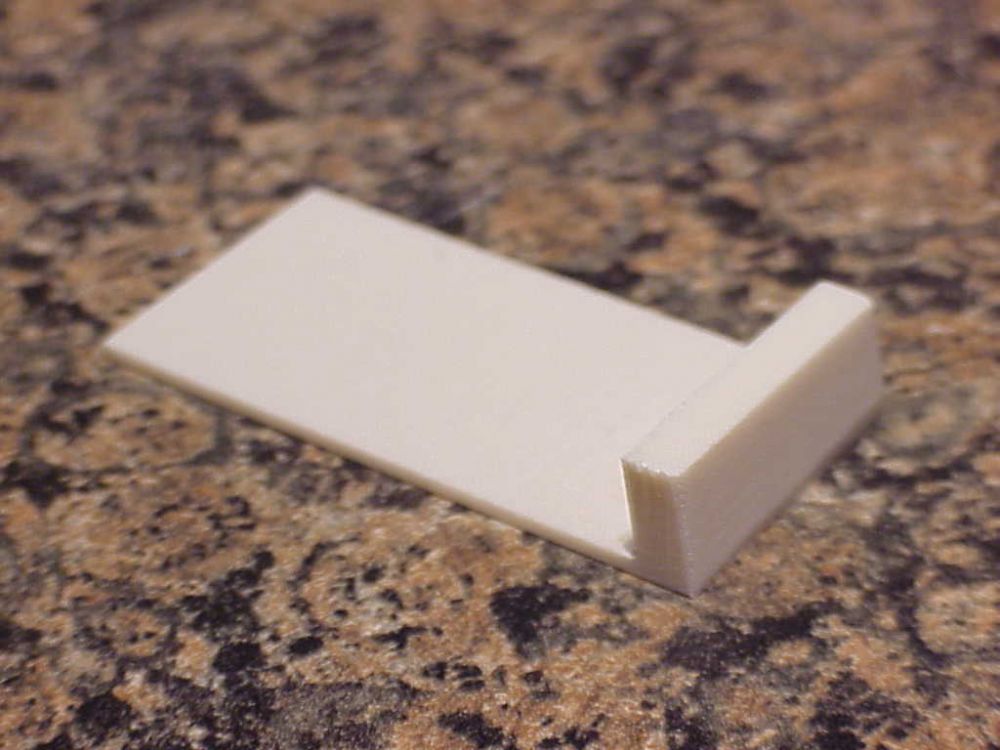

Tip Armor™ Bass Bow Tip 83 Degree

Tip Armor™ Bass Bow Tip 83 Degree

| Part # | Price | Purchase |

| TABASS83/311 | $17.00 |

Tip Armor™ bass bow tip with 83 degree milled head.

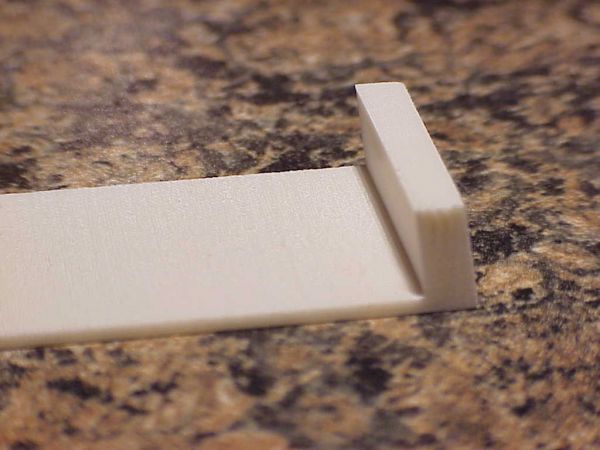

Made to industry standard size of .875+" width X 1.90+" length X .300++" head height. Floor is 1.3 mm + thick. Head is precision milled at 83 degrees.

Made of AMW-814, a polymer composite. This polymer has been formulated for strength and flexibility and engineered in a way to allow artisans to work the material with ease utilizing standard carving and bow making tools. This material bends with finger strength and holds its bow tip curve for application without the typical process of soaking and press-forming. Simply bend the floor to the needed curvature and glue into place. Then shape, sand and carve as you would mammoth ivory or other materials. Several glues work well including hide glue and superglue (CA glue) which works very well.

These incredibly well machined and strong bow tips are made exclusively here at David Warther & Co.. These have been developed to solve the need for a highly durable bow tip that can enter international trade because they are made of a polymer rather than a natural material and yet they are sold at a reasonable price. Mid-size international orders ship free - see shipping page for details. These also provide the bow making and repairing community with an extremely durable bow tip that is a time saver for application artisans. Bow makers are finding this material easier to work than the natural materials such as bone and fossil ivory and far easier to work than the plastic and casein based bow tips.

Application information:

1) The angled head area itself has been precision milled and needs no sanding or shaping. It is ready to go for you. Prior to gluing, the artisan should remove 90% of the material that will not be seen in the final product. You are taking the rectangular shaped tip and working it into being a U shaped tip before gluing it. After attaining the U shape then gently bend the tip in your fingers. A gentle bow/curve can be put in the floor by doing this and this makes gluing easier.

2) The floor has been very finely cut. This cut surface is ready to go for any glue. Do not sand this surface. You can use hide glue, epoxy glue, gorilla glue or CA super glue. We recommend Super Jet medium viscosity professional grade cyanoacrylate glue (available on Amazon as the red label as opposed to the Jet brand with blue label).

3) Sand the fiber or wood surface you are going to glue the tip to with 150 or 220 sandpaper. You are sanding this surface to clean it up so the glue adheres better to it. Again, no need to sand the floor of the tip itself.

4) After gluing the tip on to the bow, the head can be finished to size and can easily be sanded and hand buffed with any paste wax. A hand buffing cloth will polish it up - a T shirt will do!

5) Here is a finishing technique for the face of the tip after it has been applied, submitted by bow maker Rodney Mohr :

"I go through 150 grit to take it down to final thickness then 400 and 2000 grit. I then use a Sunshine brand polishing cloth to bring up the shine. It is a yellow cloth that must have a wax and/or oil along with the abrasive. You can get the Sunshine polishing cloth from Amazon where it is sold as 3 cloths in a packet. The cloths need to be kept in a sealed bag to keep them fresh and clean. One of my dogs wants to shred them to pieces, so I can't leave them on my bench. They are also very good for silver and other things as well."

In addition to ease and speed of application is the strength and durability factor. This material is simply as tough as nails and can take a lot of punishment. Tip Armor™ is a trademark of David Warther & Co..

Additional Views

Don't forget the bags!

Violin, Cello & Bass Bow Bags.

PLASTIC BAGS: Our plastic bags are heavy bags at 3 mil thickness. They are 2.75" wide X 36" length and are clear. These are available in groups of 5 or in packages of 100.

Plastic Extra Heavy Duty Bow Bags